Careinder's high-performance dynamic seals meet BP and ANSI equipment standards, as well as the ever-changing environments of centrifugal machines in a wide range of industries.

Technical Data Product testing

Our materials specialists are able to perform a range of testing services to ensure quality and optimal performance.

Technical collaboration is a critical focus of Careinder and is a key benefit to our customers. Being able to test our own products we use that performance data to continuously improve and innovate.

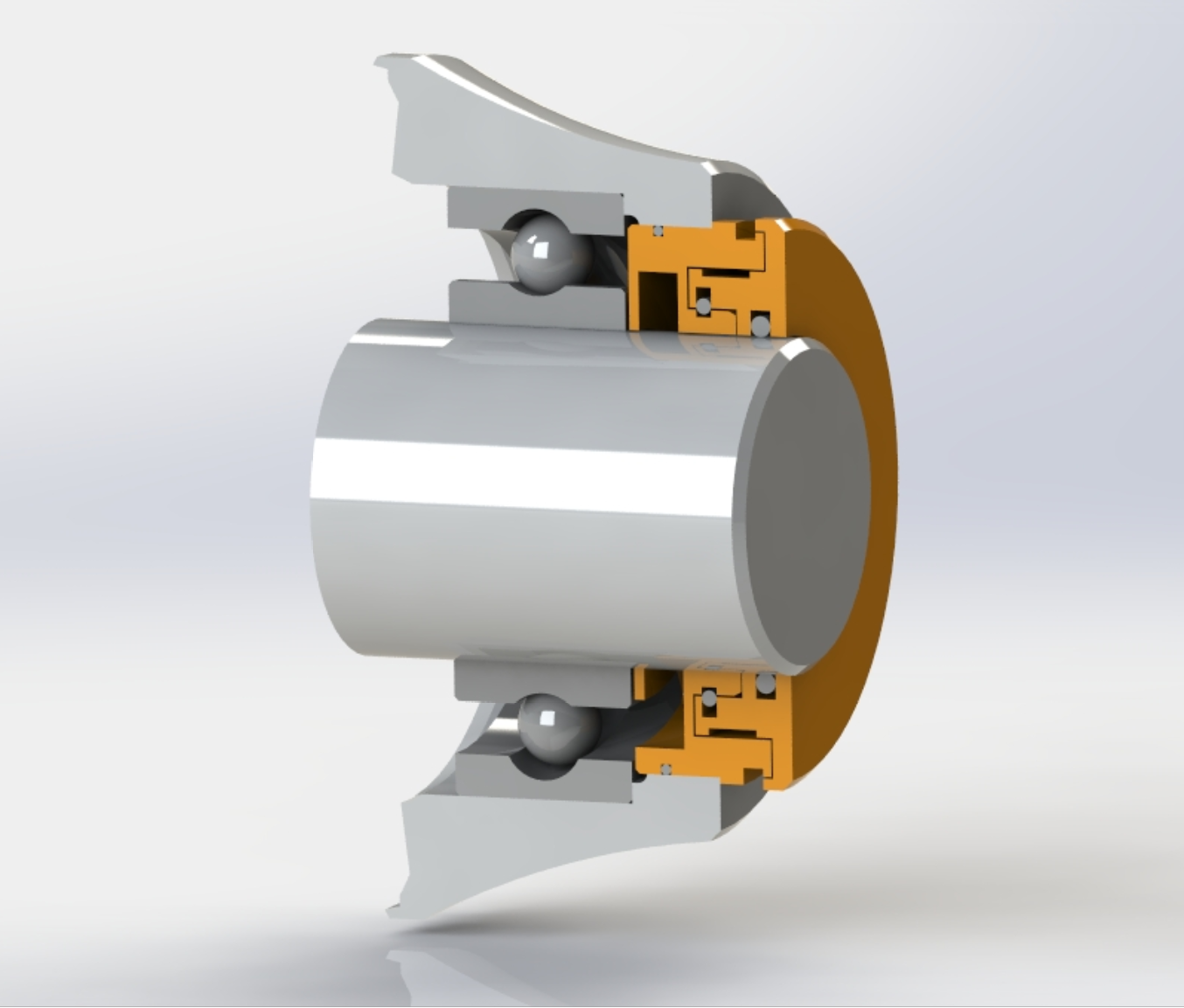

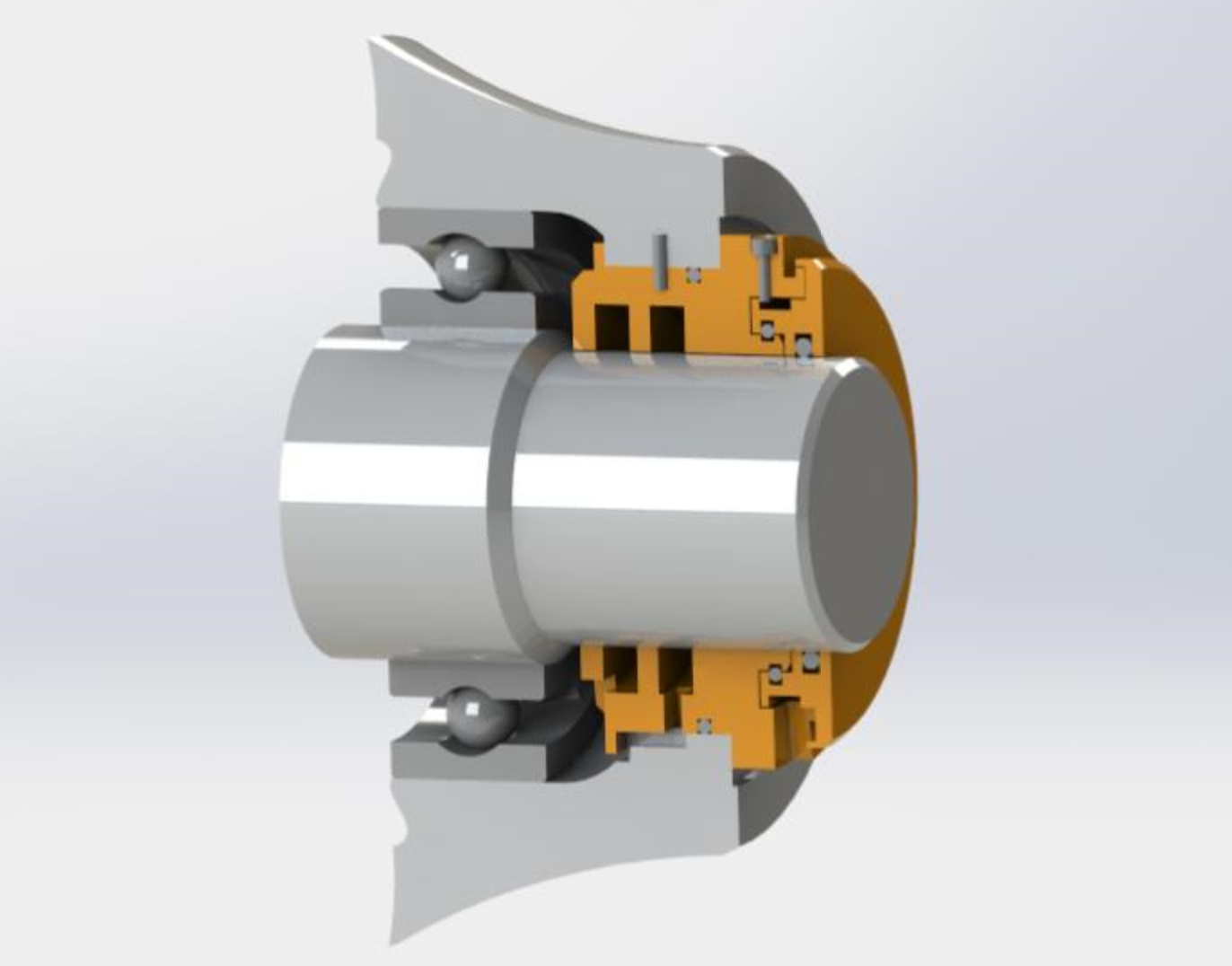

Careinder General Industry-CGI

CGI is designed for motors, gearboxes and OH series pumps.

The design is non-contact and does not wear out the mechanical shaft. The advanced labyrinth design allows the housing to exhale as the shaft rotates.

The design prevents external contamination and lubrication losses and is ideal for oil lubrication applications.

Technical Data

- Standard Material – Bearing Bronze and 416 Stainless Steel

- Radial Movement – 0.50 mm

- Axial Movment-0.50mm

- Temperature Range – up to 550°C

- Speed – 10,000 sfpm

- Shaft Size – 14.75 mm to 50.00 mm

- O-Ring Material – FKM,NBR,silicone,EPDM,Aflas

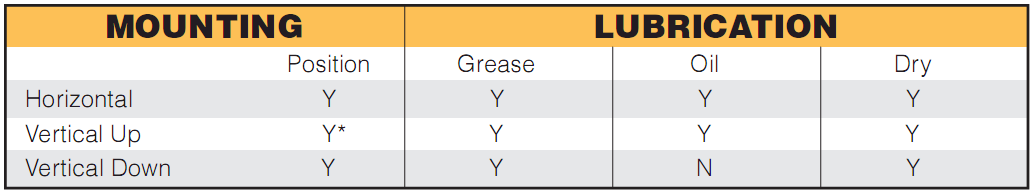

Careinder Forced oil Lubrication-CFL

Permanently protect steam turbine bearings in both high and low temperature environments.

CFL design seal utilize multiple features to ensure effective and permanent bearing protection against contamination ingress and lubrication loss on process steam turbines. They can be custom engineered to meet the requirements of your application and operating environment.

Technical Data

- Standard Material – Bearing Bronze and 416 Stainless Steel

- Radial Movement – 0.50 mm

- Axial Movment-0.50mm

- Temperature Range – up to 550°C

- Speed – 10,000 sfpm

- Shaft Size – 14.75 mm to 50.00 mm

- O-Ring Material – FKM,NBR,silicone,EPDM,Aflas

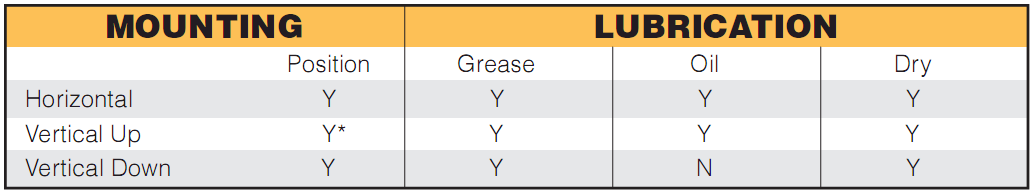

Careinder Split Design-CSD

Technical Data

- Seal Material – Bearing Bronze

- Radial Movement – 0.50 mm

- Axial Movment-0.50mm

- Temperature Range – -40 to 250F(-40 to 121C)

- Speed – 10,000 sfpm

- Shaft Size – 28 mm to 50.00 mm

- O-Ring Material – FKM,NBR,silicone,EPDM,Aflas

Retain :Grease and oil splash (operating oil level in cavity between seal and bearing must emain below inboard oil drain-back port of seal )

Exclude:Heavy water spray and dry contaminants from bearing cavity

equipment:For field retrofits where equipment can not be uncoupled or disassembled. Requires no wear sleeves or shaft refurbishment. Motors, pumps, mixers, gearboxes, blowers and custom equipment.

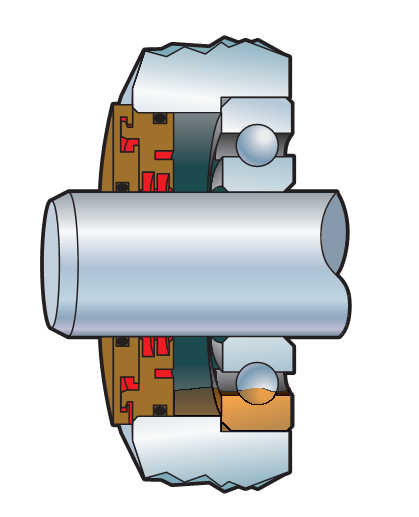

NFS

The NFS design is the first and only metallic seal that is unitized without internal o-rings or locking rings. NFS patented labyrinth technology does not rely on a simple o-ring for bearing protection.

Technical Data Product testing

- Seal Material – Bearing Bronze

- Radial Movement – 0.55 mm

- Axial Movment-0.80mm

- Temperature Range – -40 to 250F(-40 to 121C)

- Speed – 10,000 sfpm

- Shaft Size – 14mm to 50.00 mm

- O-Ring Material – FKM,NBR,silicone,EPDM,Aflas

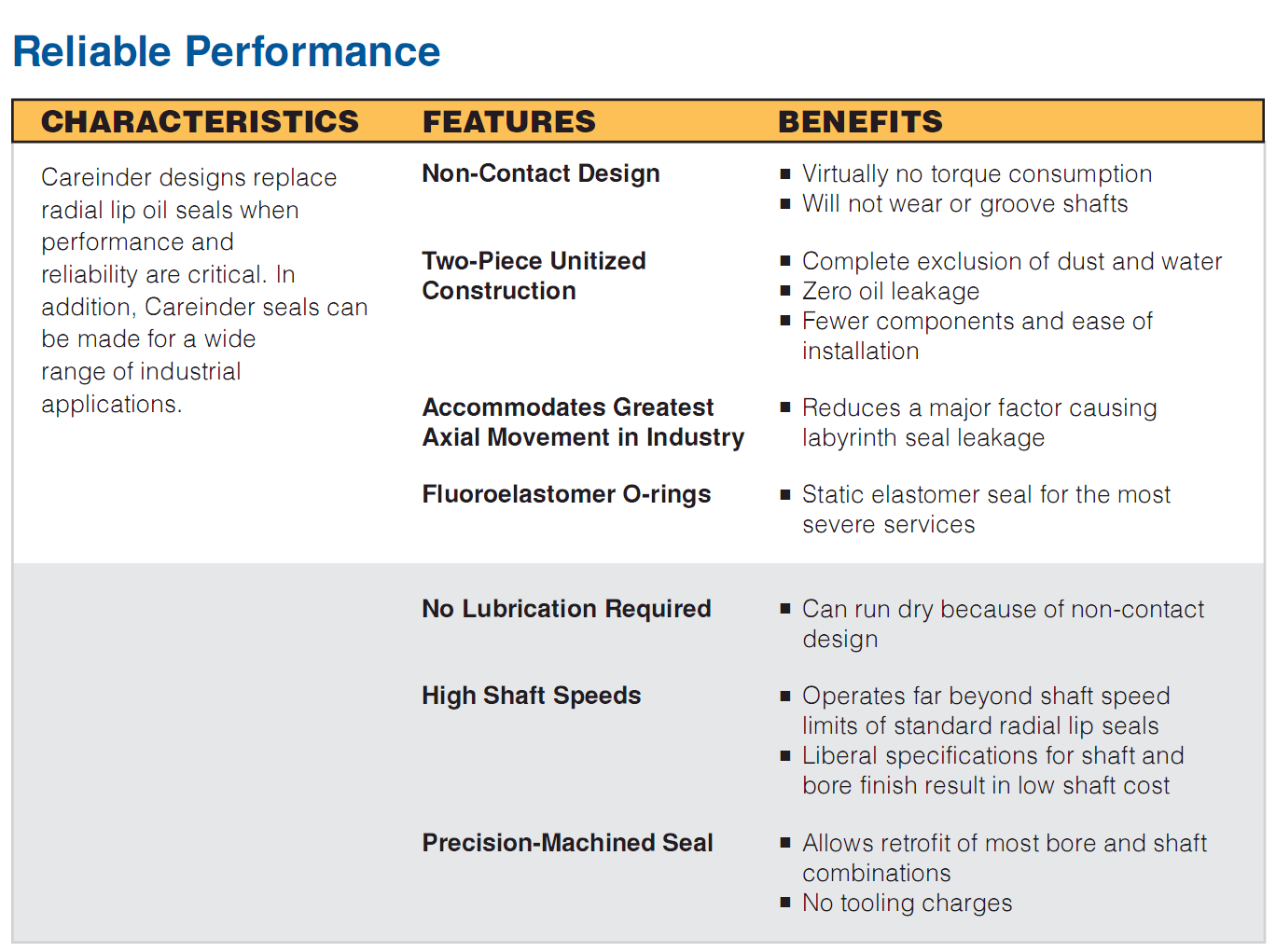

The CDA Series provides exceptional reliability and standardization over a wide variety of industrial applications and equipment.

1.Lower total cost of ownership from advanced seal design features that enable superior reliability.

2.Broad application flexibility assured by comprehensive range of pre-engineered configurations and materials; custom solutions also available.

3.Reduced operating costs via standardization to CDA Series, which enables less inventory, greater flexibility, less downtime and longer seal life.

The GSA Series for compressors,API PUMP and reactors

1.Extended service life via high torque-capable, anti-rotation lugs that minimize distortion and wear.

2.Decreased inventory costs and increased design flexibility owing to parts interchangeability between single and dual seal arrangements.

3.Greater efficiency from standard distribution ring connected to the seal’s flush port.